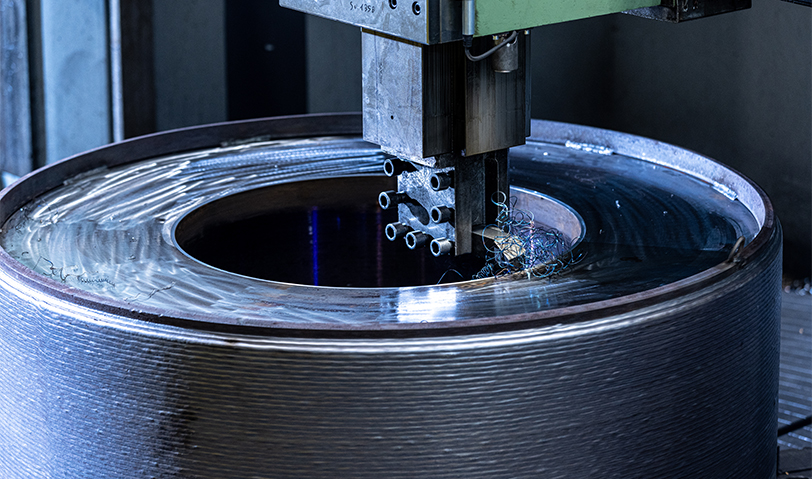

Soluzioni personalizzate per prestazioni ottimali

Al centro del nostro impegno per l'eccellenza mettiamo la ricerca di soluzioni su misura capaci di allinearsi alle esigenze di ogni cliente.

Che si tratti di rigenerazione o fornitura completa i nostri servizi consentiranno di estendere la vita operativa dei tuoi macchinari, ottimizzando fattori chiave come prestazioni, durabilità ed efficienza.